ExxonMobil's EV battery revolution: From oil giant to energy storage innovator

Oil major pivoting from fossil fuels to power the electric vehicle era

America's largest oil firm, ExxonMobil (market capitalisation: $485 billion), is pivoting from fossil fuels to power the electric vehicle (EV) era with groundbreaking battery advancements.

Once a pioneer in lithium-ion technology, the company is now leveraging its chemical expertise to address key bottlenecks in EV adoption: battery life, charging speed, and supply chain security.

This resurgence comes amid slowing oil demand and booming EV sales, projected to hit 25 million units globally by 2025.

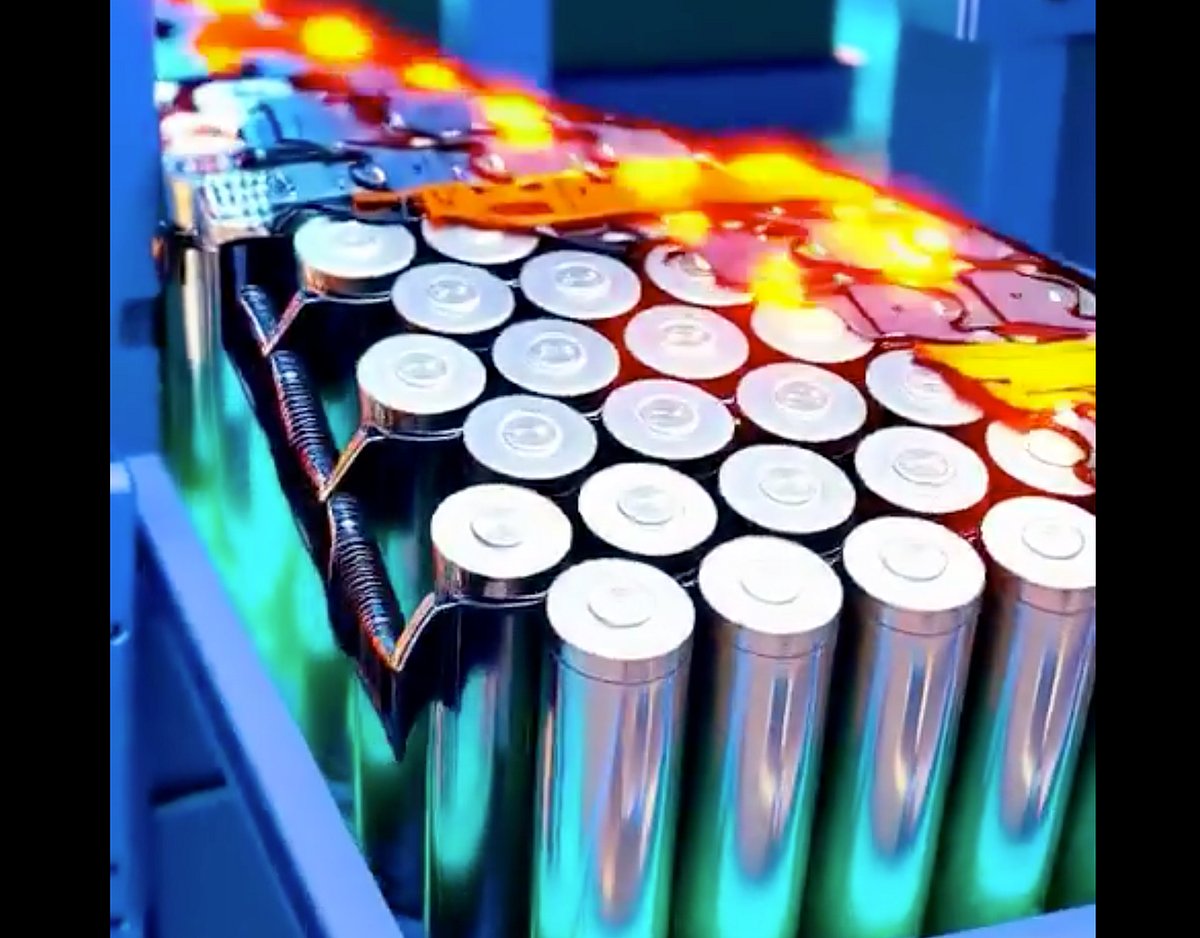

At the heart of ExxonMobil's breakthroughs are enhancements in lithium-ion battery chemistry, particularly the anode — the negative electrode where lithium ions are stored during charging.

Traditional vs synthetic anodes

Traditional anodes rely on graphite, but ExxonMobil's innovation introduces a novel synthetic graphite variant, a "new carbon molecule" that boosts battery performance.

This material extends cycle life by up to 30%, enabling EVs to endure more charge-discharge cycles before degrading.

It also improves energy density, potentially increasing driving range by 30% and slashing charging times, making long-haul electric travel more viable.

By refining the intercalation process — where lithium ions slot between graphite layers — the chemistry minimises degradation from repeated use, a common pain point in current batteries.

Lithium-ion battery pioneer

This story traces back to the 1970s, when ExxonMobil chemist M. Stanley Whittingham invented the foundational lithium-ion battery.

Amid the oil crisis, Whittingham developed the first rechargeable prototype using a titanium disulfide cathode and lithium-aluminum anode, earning him a share of the 2019 Nobel Prize in Chemistry alongside John B. Goodenough and Akira Yoshino.

Synthetic vs natural graphite

Though safety issues stalled commercialisation, his intercalation concept laid the groundwork for today's multibillion-dollar industry.

Central to ExxonMobil's edge is synthetic graphite, a lab-engineered form of carbon produced from petroleum byproducts or other feedstocks, rather than mined from the earth.

Unlike natural graphite, which dominates 70% of the market and faces supply risks from geopolitical hotspots like China, synthetic graphite offers superior purity and consistency.

It's less labor-intensive to produce, scalable via ExxonMobil's refineries, and environmentally friendlier, with lower land use and emissions.

This makes it a game-changer: it outperforms mined alternatives in conductivity and stability, directly enhancing battery efficiency and reliability.

By acquiring Superior Graphite's assets in September 2025, ExxonMobil aims to ramp up U.S. production, reducing reliance on imports and bolstering domestic EV manufacturing.

Extended range

The new chemistry is undergoing rigorous testing by several major EV manufacturers, though specifics remain under wraps to protect intellectual property.

Collaborations with battery giants like SK On and LG Energy Solution — via memorandums for lithium supply — suggest these firms are likely involved, integrating the graphite into prototypes for vehicles from partners like Ford and Hyundai.

Early results indicate faster charging and extended range, critical for fleet operators and consumers alike.

Looking ahead

ExxonMobil's path is clear: commercial synthetic graphite production by 2029, paired with lithium output from Arkansas brine deposits starting in 2027.

Using a process called "direct lithium extraction", the firm targets supplying enough for over one million EVs annually by 2030, all while cutting costs and emissions.

This $30 billion low-carbon investment, including carbon capture synergies, positions ExxonMobil as a bridge between oil and renewables — securing energy independence, creating US jobs, and accelerating the shift to sustainable mobility.

As CEO Darren Woods noted, it's a "revolutionary step change" toward a net-zero future, proving even oil titans can recharge.

Sign up for the Daily Briefing

Get the latest news and updates straight to your inbox

Network Links

GN StoreDownload our app

© Al Nisr Publishing LLC 2026. All rights reserved.