Filipino scientists create 'transparent aluminium' breakthrough

Ateneo-led team develop low-cost, green way to produce transparent aluminium oxide

Manila: A team of Filipino and Japanese scientists, has discovered a cost-effective method to produce transparent aluminium oxide (TAIOx).

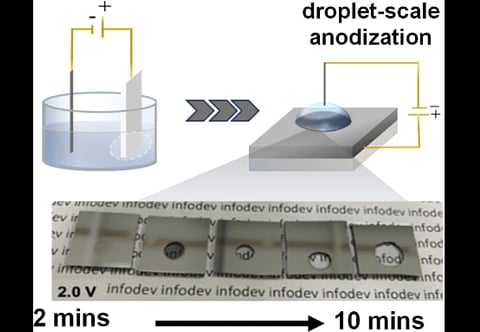

Their innovative technique, called “droplet-scale anodisation,” requires only two volts of electricity — less than a household AA battery — making it simpler and more environmentally friendly than traditional methods.

Ateneo-led team

The team, led by Ateneo de Manila University researchers, explained that conventional TAIOx production relies on high-powered lasers, vacuum chambers, or hazardous acids, making it expensive and complex, the university's website reported.

In contrast, the researchers’ approach uses microdroplets of acidic solution and an electric current, leveraging the "electrowetting" effect to precisely control the anodization process.

Breakthrough

This breakthrough could revolutionise industries by making TAIOx more accessible for applications such as touchscreens, ultra-durable coatings, and miniaturized electronics.

The findings were published in the journal Langmuir.

The sci-fi franchise Star Trek has featured TAIOx as the material used for starship windows and spacefaring aquariums.

The research team includes Marco Laurence M. Budlayan and Raphael D. Guerrero from Ateneo de Manila University, along with Juan Paolo S. Bermundo, James C. Solano, Mark D. Ilasin, and Yukiharu Uraoka from the Nara Institute of Science and Technology, in Ikoma, Japan.

Use cases for TAIOx:

Aluminum is a durable material, with a 660.3 °C melting point. Transparent aluminum oxide (TAIOx) has several key applications across various industries:

Touchscreens and displays: Used as a durable, scratch-resistant coating for smartphones, tablets, and other electronic screens.

Ultra-durable vehicle coatings: Enhances the strength and transparency of windshields, mirrors, and protective layers for cars and aircraft.

Miniaturised electronics: Helps create insulating, transparent layers for next-generation microchips and flexible electronics.

Optical and laser components: Used in high-precision lenses, optical windows, and laser-resistant materials.

Defense and Aerospace: Can be applied to bulletproof glass, reinforced cockpit windows, and spacecraft shielding.

Medical Equipment: Ideal for biosensors, transparent medical implants, and protective coatings for lab instruments.

Energy-efficient windows – Could improve insulation while maintaining transparency for smart windows in buildings.

The breakthrough, when commercialised, makes TAIOx more affordable and accessible, opening doors for innovations in various industries.