From lithium-ion to sulfur lithium and sodium-ion: How do electric vehicle batteries work?

Cathode is the single most-expensive element, accounts for up to a third of a cell's cost

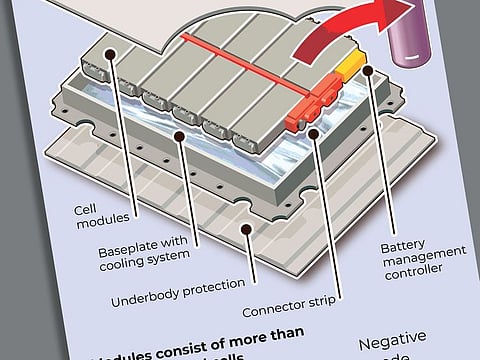

The individual cells in most rechargeable EV batteries today have the same basic components: Electrodes, electrolyte and separator. The positive electrode is called the cathode; the negative electrode is the anode.

Cathode: Most expensive component

The cathode is the single most expensive element, accounting for up to a third of the cost of a battery cell. Most lithium ion batteries today use one of two types of cathodes: Nickel cobalt manganese (NCM) or lithium iron phosphate (LFP).

Charge/discharge

When the battery is being used — and its stored energy is being discharged — tiny particles (called ions) inside the battery travel from the anode to the cathode, through a chemical solution called the electrolyte, creating an electrical current.

When the battery is being recharged, those particles then flow back from cathode to anode.

Lithium's role

Because lithium is stored in both cathode and anode, these cells are generally known as lithium ion. The separator, as its name implies, keeps the cathode and anode from touching each other and causing an electrical short.

Anode, separator

Most anodes use graphite or a silicon-graphite blend.

The separator often is made of porous plastic to enable ions to flow between the electrodes. The electrolyte is a liquid, gel or solid blend of chemicals and additives; ions travel between the positive and negative electrodes through the electrolyte.

Different materials

Different materials can be used in each of the battery's key components; different combinations will have different effects on various aspects of battery performance, from how much energy can be stored to how quickly or how many times the battery can be charged.

Future battery cathode chemistries

Two future battery cathode chemistries — sodium ion and lithium sulfur — could unlock the door to more affordable electric vehicles while reducing reliance on scarce, expensive and unsustainably mined raw materials. But neither is likely to make it into volume production before 2025.

A number of startups are betting on two cheaper and more widely available raw materials — sodium chloride and sulfur — to bring down battery costs and reduce the industry's reliance on China.

Sodium ion batteries do not need lithium, cobalt or nickel — the three most expensive battery ingredients — but need more research and testing to increase their energy density.

Sulfur lithium

Sulfur lithium batteries still rely on lithium in smaller quantities, but do not need nickel or cobalt. Sulfur has huge potential because of its capacity to hold a lot of energy, but startups have to overcome the fact that it is also highly corrosive.

Experts like Shirley Meng, chief scientist at the US Argonne National Laboratory's Collaborative Center for Energy Storage Science, say diversifying battery materials is critical "to keep the cost low and the supply secure."

Some key elements of each chemistry:

Sodium-ion

Replaces: Lithium

Supply: Abundant

Cost: Extremely low

Environmental Impact: Benign

Recyclability: High

Reliance on China: No

Typical Anode Material: Hard carbon

Upside: High stability, less flammable than lithium ion, easy to refine, uses same manufacturing equipment as lithium ion

Downside: Low energy density, low cycle life, heavier than lithium ion

Lithium sulfur

Replaces: Nickel, cobalt

Supply: Abundant

Cost: Extremely low

Environmental Impact: Lower than cells that use nickel and cobalt, but lithium still not sustainably mined and refined

Recyclability: High

Reliance on China: No

Typical Anode Material: Lithium metal

Upside: High energy density, long range, lighter weight than lithium ion, potential for use in electric aircraft

Downside: Limited cycle life, potential energy loss, electrode corrosion.

Sign up for the Daily Briefing

Get the latest news and updates straight to your inbox