UAE to use 3-D printed knee joints for replacement by 2019

Innovative use of technology will customise patient needs

Dubai: The future is looking brighter for patients in the UAE needing knee surgery to return to an active life without pain, says a leading surgeon.

The UAE is less than a year away from using three-dimension al (3D) technology for knee surgery, providing the ‘right’ customised fit for each patient and reducing recovery time, said Dr Samih Tarabichi, orthopaedic surgeon, director of Burjeel Hospital, Dubai.

Dr Tarbichi spoke on the sidelines of the International Conference on Joint Replacement (ICJR) held in Dubai. from March 22-24.

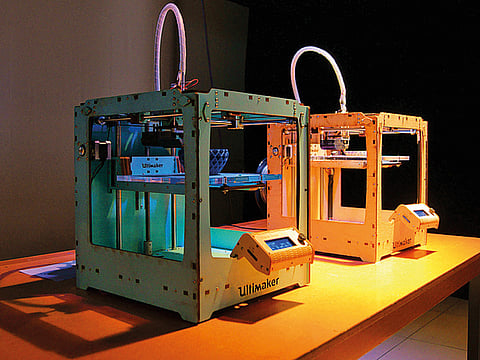

A 3D printed brace (top), a printed implant (above left) and a guide for knee replacement (right), a technology that allows doctors to create a virtual joint and practise before a surgery.

“Three-dimensional printing is the future of orthopaedics and its application in this field is enormous since the bone is a rigid structure and this technology can be applied to accommodate the rigid as well as the soft tissue structure,” he told Gulf News in an interview.

The way doctors get an exact fit is using a patient’s CT scan and printing the exact image right down to the last millimetre with all the contours much like choosing a tailored garment over a ready made one.

Elaborating on the multiple uses of 3D technology in printing various parts of the knee anatomy, Dr Tarabichi said they were looking at five major applications.

“The 3D implant made from titanium, which is compatible with the human body, will be used to replace a body defect like a gap of major loss of bone owing to a tumour surgery or trauma. It will also be used in total joint replacement where the printed implant exactly matches the size of anatomy of that particular patient’s knee.”

The 3D implant will be used to replace a body defect like a gap owing to a tumour surgery or trauma. It will also be used in total joint replacement where the printed implant exactly matches the size of anatomy of that particular patient’s knee."

New 3D printing will make it possible for Asian patients to get an implant that is exactly tailored to their individual needs as current implants manufactured by western companies work best for anatomy of people other than Asians and have to be adapted to fit a small-stature patient.

Dr Tarabichi said: “Now the advantage of the 3D implant is that you cannot only match it in the Asian patient, furthermore you could design something that is personalised to their needs allowing them to function well and allowing them to have a full bending.”

The technology is also now being tweaked to be used in complex fractures where plates of specific sizes can now be created to stabilise a fracture using a patient’s exact CT scan.

Printed implants are being used to manufacture orthotics or braces in cases of amputations where individual patients have requirements of specific fixations, especially in cases of complex fractures.

Dr Tarabichi explained: “Braces are usually made to stabilise the external extremity and that immobilisation means that this brace must fit on the stump of an amputated limb which in many cases is irregular. The breakthrough (with 3 D printing) is that we can make a coverage that will fit exactly to the size of the patient,” he said.

Perhaps one of the most important use of 3D printing technology in orthopaedics is for learning where doctors are able to use the CT images to create a virtual joint and practice before conducting an actual surgery, said Dr Tarabichi.

Illustrating with an example, Dr Tarabichi said: ‘In case of corrective surgery for a deformity in the leg whether it is a knocked knee or bow leg in some cases we correct the surgically to preserve good function for the patient. Initially what we used to do is correct it based on our assessment intraoperatively where the surgeon assesses the correction required goes ahead.

But now the technology has evolved and 3D imaging for the affected limb enables an orthopaedic surgeon to correct the deformity on a virtual model first and also customise the plate according to the need of the patient where the supplier makes special guides as per the 3D images giving the doctor an idea where to cut with minimum damage to the bone.

Dr Tarabichi added that he had already conducted such a surgery using 3D guides in Dubai which have been prevalent since 2011.

Facts about 3D bone printing

■ The material used is titanium

■ It will be used in Dubai by 2019

■ 3D implants will cost 15 per cent more than traditional implants initially till local manufacturing is set

■ Health insurance cover for implants will be worked out once it is introduced in the UAE