Just like Daniel Day-Lewis' recalcitrant Daniel Plainview in the Oscar-winning There Will Be Blood, Donnie Wilson likes to think of himself as an oil man. But the 51-year-old entrepreneur from Illinois, US, no longer has an interest in helping people drill for black gold; 20 years ago he realised there was more money to be made if he could clean up - in both senses - in the field of oil-spill removal. His firm, Elastec/American Marine, is now a leading light in the industry, and Donnie knows how to round up spilled oil like no one else. But what sets him apart from his peers is what Donnie does next: the go-getting CEO grabs a match, throws it at the slick and stands well back.

"There was a gap in the market for us," says Donnie, reminiscing about his company's calculated withdrawal from the business of making machinery for oilfield companies. "There was also the cyclical nature of the market - when prices were good, business was up, when they were down, it wasn't. I wanted something more stable."

The straight-talking businessman now finds the security he sought designing and manufacturing products that help people tackle the planet's seemingly never-ending succession of oil spill disasters.

Dealing with Deepwater Horizon disaster

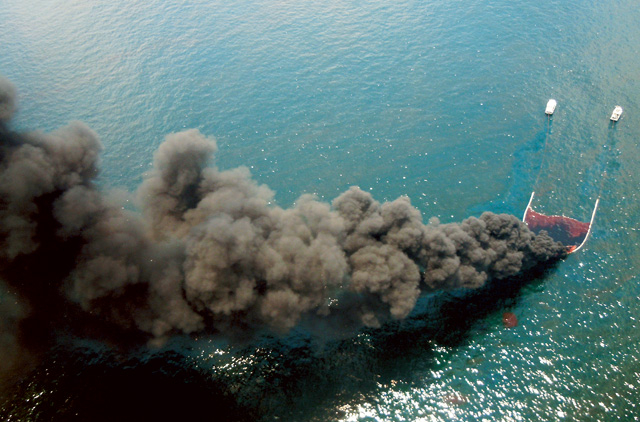

Donnie's company isn't normally to be found at the scene of the crime, so to speak, but when BP called following the catastrophic Deepwater Horizon explosion on April 20, 2010, which killed 11 people and started spewing millions of barrels of oil into the Gulf of Mexico, Donnie assembled a 240-strong team and rushed to the site. It was a rare sliver of good news - here was a man who would round up thousands of gallons of oil and ignite it, and all, implored the experts, without further damaging the environment.

"Whether the oil was burned in your car or at an oil spill," says Donnie, "tests showed that it was basically the same greenhouse gases being released."

At the heart of the company's success in the Gulf of Mexico was its invention, ‘fire boom'. A little like a long, plastic snake that floats, the boom is towed by two boats that use it to round up floating oil and form a slick that is thick enough to hold a flame - 3mm at least.

The boom has to be replaced after 20 hours of burning, but with BP ready to write cheques to anyone who could help them, money was hardly an issue.

"We had fires that were 100m high," recalls Donnie. "They were monsters. There were career fire-fighters on board our boats and they just couldn't get over the size of these things."

Donnie led the operations on the water for the best part of three months; it was a challenging time. "We were working 16-18 hours a day. All we wanted was a meal and a warm bed."

A different approach needed

As the oil kept pouring out from the ruptured oil well, the size of the recovery efforts multiplied. It seemed at times like they faced a problem without an ending, oil gushing unchecked into the ocean for weeks on end. "With smaller spills you can often deal with the problem using skimming vessels and it's often a matter of days to deal with," says Donnie. "This was different - there were none of those same expectations of volume or how long it was going to last."

A spill on such a scale did, however, lend itself exceptionally well to Donnie's incendiary solution. "With burning, you can get rid of large quantities at the source without any need for storage or transportation," he says.

"Once you light the oil it's ablaze within minutes, and all it leaves is a small residue, like asphalt."

The reward for Donnie's prolonged spell on the waves was a classic success story - the 300,000 barrels they burned was more than was spilled during the Exxon Valdez disaster.

Last October, Donnie and his colleagues scooped top prize in the $1m Wendy Schmidt Oil Cleanup X-Challenge, a sister competition to the X-prize space contest won by Paul Allen and his SpaceShipOne in 2004. The prize wasn't for their fire boom, though, it was for a brand new Elastec invention, a machine capable of recovering oil from the ocean's surface at a rate of nearly 5,000 gallons per minute.

Remarkably, the product had still been on the drawing board when the contest was first announced in the summer of 2010.

Encouraged by their success off the coast of America, Donnie cajoled his staff into working late, found $600,000 to make a prototype, and tinkered around the clock to meet the competition deadline. "It might otherwise have taken us ten years," he admits.

The result spoke for itself - a devastatingly impressive device the size of a truck that lapped up oil like a cat slurps down milk.

Up against more than 300 entries from all over the world, it stood alongside designs from the sharpest brains in the business - and delivered the goods in spades.

The million dollar first prize was the ultimate pat on the back for Elastec, and provided proof that its clean-up bow had multiple strings.

When National Geographic compiled its list of the Most Hopeful Energy Developments for 2011 this January, it came as no surprise to see Elastec right near the top.

While these triumphs have provided the company with rich material for their history books, they probably won't prove to be Donnie's most enduring memory of the past 24 months. That honour goes to the local shrimp boat captains who became the backbone of his clean-up operations when in the Gulf of Mexico. "They were an essential part of the team, totally committed," says Donnie.

"They were very competitive, too, always talking about who had had the longest burns and the highest ones."

If he'd have known he was going to spend so long with these fisherman, however, Donnie says he'd have done a little more preparation work up front. "Yeah," he chuckles, "I'd have watched Forrest Gump a few more times!"