Honda successfully tests reusable rocket, a huge step in its aerospace ambitions

Experimental rocket reachs 271.4m, lands within 37 cm of the target

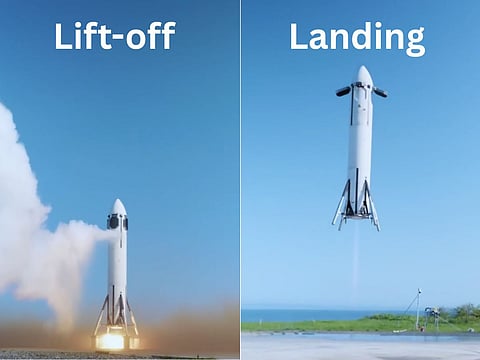

Honda has successfully tested an experimental reusable rocket, reaching 271.4 metres and landing within 37 cm of the target after 56.6 seconds

This marks a significant step in their aerospace ambitions.

This achievement follows Honda R&D Co Ltd's ongoing research into reusable rocket technology, initiated in 2024 with engine combustion and hovering tests in Taiki Town, Hokkaido, Japan, reflecting their commitment to sustainable space access.

The test aligns with global trends in reusable rocket development, as evidenced by SpaceX's Falcon 9, which has flown over 300 times since 2015, drastically reducing launch costs and enabling frequent missions like Starlink deployments.

Game-changer

Honda’s focus on reusability echoes findings from a 2018 Acta Astronautica study, which modelled that reusable rockets could cut specific launch costs.

In their study, Pozo et al. analysed Falcon 9's economic impact. Using lifecycle cost modelling, they estimated reusability cuts specific launch costs by 30–50% after 10 flights, with breakeven at 3–5 reuses.

Their simulations accounted for refurbishment variability, showing net savings even under failure rates up to 5%.

More reusable rockets

The successful test occurred amid growing international competition in reusable launch vehicles, with China’s Long March 8R and Europe's Themis program also advancing, though facing challenges in funding and engineering.

Honda's initiative is part of a broader strategy to inspire new possibilities in human mobility, as stated in their corporate vision, potentially impacting future satellite launches and space-based services.

Why reusable rockets are a game-changer

The advent of reusable rockets has revolutionised space exploration, slashing launch costs and accelerating mission frequency.

Traditional expendable rockets, discarded after a single use, imposed prohibitive expenses — often exceeding $100 million per flight — limiting access to orbit. Reusability addresses this by recovering and refurbishing core components, primarily the first stage, enabling multiple flights with minimal overhaul.

SpaceX pioneered this paradigm with the Falcon 9, first achieving a controlled booster landing in 2015.

The rocket’s grid fins and Merlin engines facilitate precise propulsive landings on drone ships or pads.

By 2023, a single Falcon 9 booster had flown 20 times, demonstrating reliability.

Cutting cost of space flight

This reduces per-launch costs from ~$60 million (expendable) to under $30 million, per SpaceX disclosures.

The savings stem from hardware reuse: a new first stage costs ~$30–40 million, but refurbishment runs $1–2 million.

Propellant, at ~$200,000 per flight, becomes the marginal expense.

New Glenn

Blue Origin's New Glenn pursues full reusability, including the second stage, but faces engineering hurdles in upper-stage recovery.

China's Long March 8R and Europe's Themis program lag, hampered by state funding cycles.

A 2022 Journal of Spacecraft and Rockets paper by Zapata et al. modelled partial reusability's scalability.

Incorporating real Falcon 9 telemetry (post-2019 landings), they projected that 100+ reuses per booster could drop costs below $5 million per launch, assuming 90% hardware recovery.

Making space access more affordable

Reusable rockets democratise space, enabling constellations like Starlink and lunar missions.

Challenges persist: thermal protection degradation, engine wear, and regulatory certification for crewed flights.

As flight rates climb — SpaceX averaged one launch every 2.5 days in 2024.

The data will refine models, potentially achieving airline-like operations. The studies underscore a clear inflection: reusability is no longer experimental but the industry's economic foundation.

Honda’s recent success in launching and landing a reusable rocket signals that eventually, many others will be building rockets like this. However, by the time that happens, Starship may have already reached Mars, keeping the technological gap wide.