Dubai: The 3D printing revolution is taking place in the classroom and not on the production floor, as the industry continues to transform from a niche market into a global market, industry experts said.

“Rise in demand to reduce manufacturing cycle times and to reduce prototyping costs are the major drivers of 3D printing at schools and universities,” said Dr Conor MacCormack, CEO of Mcor Technologies.

Mcor is a manufacturer of affordable, full-colour and eco-friendly 3D printers using normal A4 paper as the build material.

He said that 3D-printed objects provide more “photorealistic qualities” that can be used to teach students and help them interact with the world around them for subjects including science, history, geography, art and more.

Ashish Panjabi, COO of Jacky’s Business Solutions and the biggest distributor of 3D printers in the region, said that as the education sector started using the latest technologies, schools and universities have also started to see the importance of 3D printers to encourage students’ advancement by enabling them to transform their ideas into physical 3D printed models.

He said the largest market for 3D printers is education. Initially, it used to come from a university level and institutions but what we are seeing now is from high schools and primary levels.

“Some places, it is part of IT curriculum and for STEM [Science, Technology, Engineering and Math] curriculum in the region for project-based learning. There are enough apps on iPads to support 3D printing. App stores like Thingiverse have over a million 3D printing designs,” Panjabi said.

Robot parts

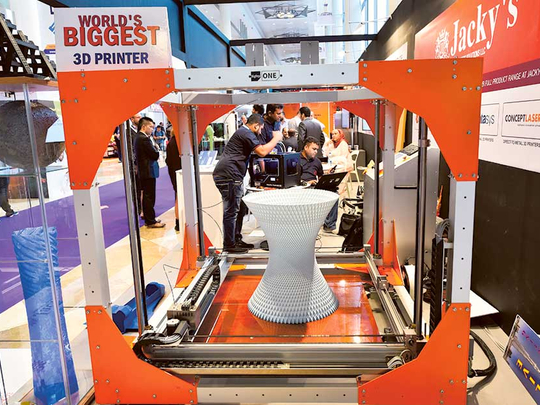

Jacky’s is showcasing the BigRep, the largest 3D printer in the world that can print from human scale robot parts to full-dimensional sculptural artworks such as chairs and tables.

According to research firm Gartner, the primary market drivers for consumer 3D printers costing under $2,500 are not household purchases but acquisitions of low-cost devices by schools and universities. The primary enterprise 3D printer market drivers are the finished-piece quality and material advances.

To be effective in education, MacCormack sees that 3D printing must be accessible to all students. The high cost of printer consumables can severely limit students’ access to 3D printing technology and be prohibitively expensive for schools.

“STEM curriculum prepares students for the real world, enabling them to expand their minds through problem-solving and logical thinking. Colour and rock-bottom operating costs are critical for manufacturers, schools and architectural firms to 3D print a high number of realistic models,” he said.

The industry is a kind of broken up at the moment into two segments, MacCormack said. First is the industrial 3D printers and they sell into the aerospace companies for printing parts and jet engines while the bio 3D printing is used for printing tissues for medical sciences.

Worldwide shipments

On the other hand, he said the desktop 3D printers are becoming cheaper and more capable.

“The way I see the future in an industrial sense, it is going to become more common for automobile, aerospace and human parts. On the desktop side, we are going to see it everywhere in offices and schools and homes,” MacCormack said.

Quoting a Gartner report, he said that 80,000 desktop printers were sold last year and it is expected to touch 140,000 this year. By 2018, it is expected to touch 1.9 million units.

According to Gartner, worldwide shipments of 3D printers will reach 496,475 units in 2016, up 103 per cent from the predicted 244,533 units in 2015. 3D printer shipments are forecast to more than double every year between 2016 and 2019, by which time worldwide shipments are expected to reach more than 5.6 million.

“The number of desktop printers is doubling every year. It is an exciting and fast changing sector. The revolution will happen in the classroom and not on the production floor. Colour is a big criterion in printing,” MacCormack said.