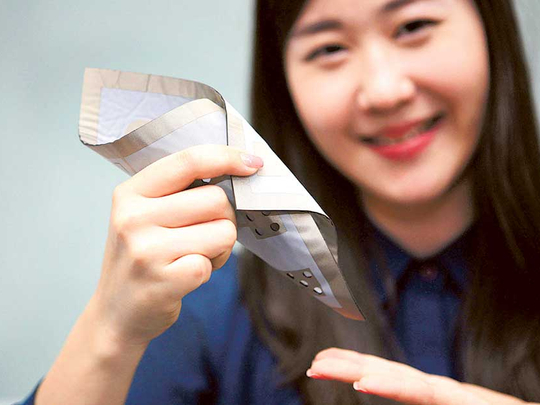

Dubai: LG Innotek announced the development of a new concept: flexible textile pressure sensors, which sense external pressure across the device and are bendable, too.

These pressure sensors, installed in medical appliances and automobiles to gauge and analyse pressure, can also be used for individual customised service.

“We tried to break away from the previous method and attempt new methods to develop innovative products,” said Changhwan Kim, Head of the LG Innotek’s R&D Centre.

He said that LG will continue to develop materials and components in various fields to provide new experiences to customers.

According to the International Data Corporation, worldwide shipments of wearable devices are expected to reach 101.9 million units by the end of 2016, representing 29 per cent growth over 2015.

Jitesh Ubrani, senior research analyst for IDC Mobile Device Trackers, said that watches and bands are and always will be popular, but the market will clearly benefit from the emergence of additional form factors such as clothing and eyewear that will deliver new capabilities and experiences.

He said that eyewear has a clear focus on the enterprise as it stands to complement or replace existing computing devices, particularly for workers in the field or on the factory floor. Meanwhile, clothing will take aim at the consumer, offering the ability to capture new forms of descriptive and prescriptive data.

Traditional fashion and fitness brands are quickly partnering with tech companies to deliver smarter clothing, bringing some much-needed attention to this nascent segment. Even conventional tech companies like Lenovo and Samsung are beginning to dabble in this space, revealing prototypes of shoes or belts.

The category stands to capture 7.3 per cent of the market by 2020 as consumers and athletes integrate fashion-tech into their daily lives.

Kim said LG Innotek’s sensors use highly elastic polyurethane material to fit the body comfortably. And they measure capacitance change caused by pressure. The company has filed thirteen patents regarding the related technologies in South Korea and secured the product quality for mass production in this year.

Former commercialised sensors were coin shaped and made of PCB (Printed Circuit Substrate Material) substrates or PET (polyethylene terephthalate) films, making them difficult to bend or deform.

“And it was difficult to measure the pressure uniformly from the large area because of its point sensing way. Even it gives feeling of irritation when the sensor touches your body,” Kim said.

The company’s textile flexible pressure sensors, however, are suitable for products such as gloves and chairs that come in direct contact with the human body.

He said that this new pressure sensor makes it possible to implement new features by utilising the pressure information in various areas such as health care and automotive.

In health-care areas, the sensor helps to improve accuracy of telemedicine. When patients wear the device or walk on a carpet, the sensor can detect body balance and acting patterns. The information from the device can then automatically be sent to the medical centre.

This product is very durable in various environments. It works normally over 240 hours from 40 degrees below zero to 80 above zero. A sensor remains functional even after an average 70kg man sits on it 100,000 times.